vertical integration controls costs, lowers prices

by:LCD Mall

2020-07-01

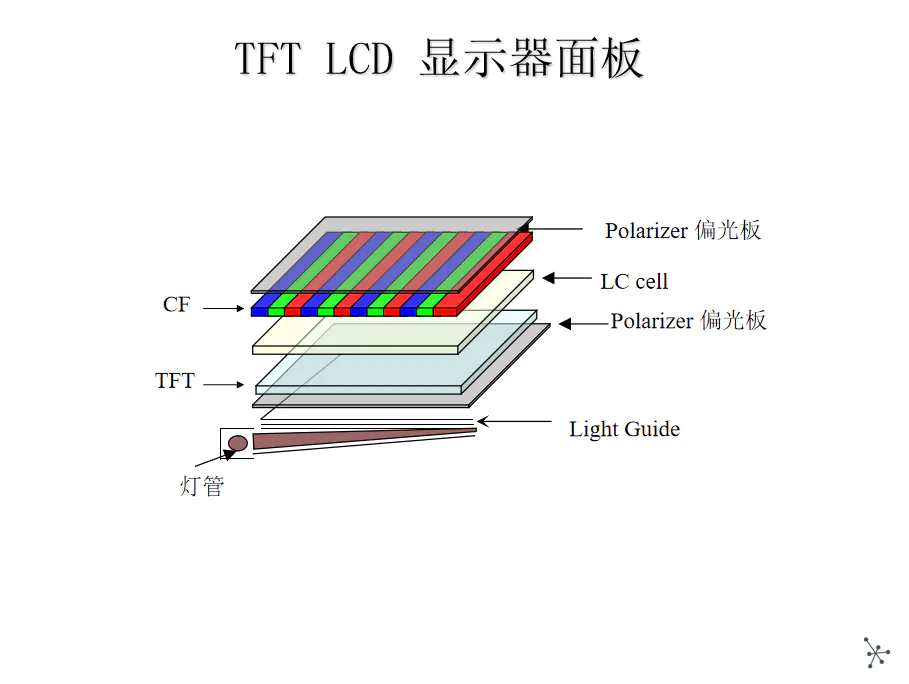

Some large manufacturers in China are shifting production processes

Have better control over cost, delivery and supply.

The benefits to buyers may include lower export prices.

High component costs, coupled with labor challenges and other factors that lead to pricing pressures, have led many Chinese companies to incorporate upstream and downstream processes in production.

While mainly implemented by large enterprises, vertical integration helps to stabilize the cost and supply of parts, speed up delivery and turnover, and more importantly curb export prices.

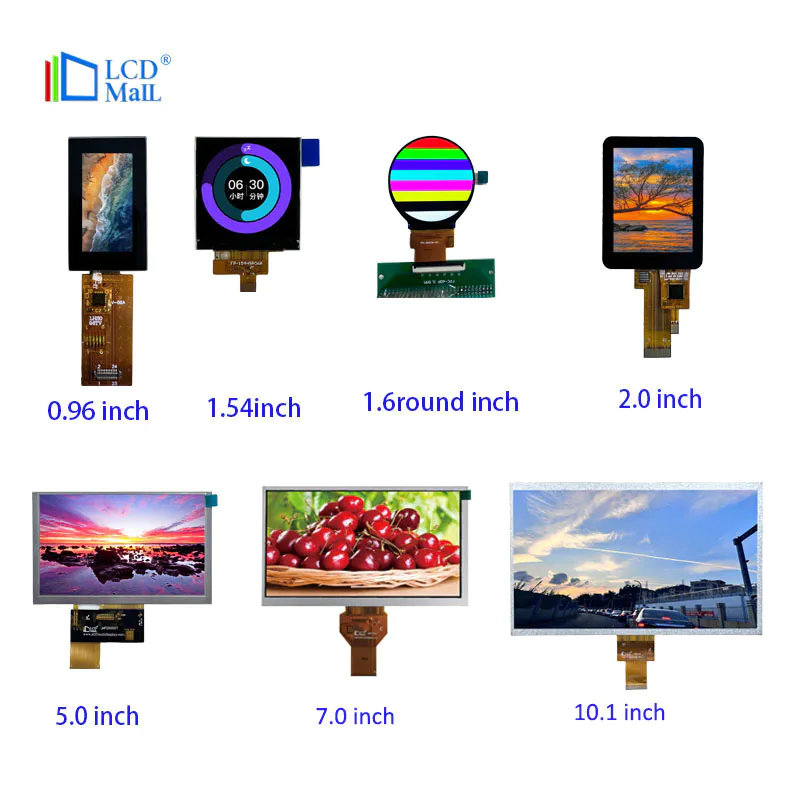

For example, the price of LCD TV is expected to decline in the next few years as more companies are investing in high production

A generation display panel in China.

At present, the component is mainly from Taiwan, Korea and Japan, accounting for about 80% of the total cost of the product.

When the display panel supplier raises the offer, Chinese TV makers have no choice but to pay.

However, government subsidies and rebates have encouraged domestic TV makers such as TCL.

Expand to LCD panel production.

Cooperation with Shenzhen Century Technology Investment Co. , Ltd.

TCL set up a joint venture

Shenzhen Huaxing Optoelectronic Technology Co. , Ltd.

Used to make display panels only.

For Building 8.

Huaxing 5g LCD panel facilities in Shenzhen, Guangdong province received 0. 5 billion yuan ($76 million)

Subsidies from the municipal government.

There are now 7 6 to 8.

5g lines in China, 5 of which are locally owned or invested, and 3 are waiting for approval.

There may be 10 high points in this country.

LCD panel facilities by the 2012 s.

When all of this is put into use, the supply may exceed the demand, which may reduce the panel cost, thus reducing the export price of LCD TV.

Absorption of downstream processes can also lead to lower prices.

Dongguan Sobo Electronic Technology Co. , Ltd.

The company used to focus on electronic components of telecom products.

Last year, the company began production of finished products, including dual-workers, power splitter, directional coupler, low-level connectors.

Noise and power amplifier and standing wave alert.

Its customers have been able to save time and money as they no longer need to purchase from different sources.

The disadvantages of integration being able to complete most, if not all, of the manufacturing process do have its disadvantages.

Companies need to spend a lot of money to implement these steps in the following areashouse.

However, the return on investment is not always guaranteed, and it may take several years to achieve it.

In some cases, the return on investment is seen 10 years after spending.

This is one of the reasons why most suppliers who are integrating processes are in the industry where government subsidies or rebates are available.

Beijing Oriental Technology Group Co. , Ltd.

For example, the limited company received a rebate of 1. 6 billion yuan ($242 million)

When it built a 6g LCD panel production line in Hefei, Anhui province.

Overcapacity is another problem because it will push prices to bottom.

This is a boon for buyers, but companies that invest heavily in integrating upstream processes have to wait longer to see positive returns.

Construction boom in 6 to 8.

The 5g facility is an example.

International players are currently actively developing OLED panels.

It is possible to score 8 points at 10: 6.

China\'s 5g production line has been put into operation, and demand in major markets will focus mainly on OLED display screens.

This could lead to a supply glut of 6.

5 to 8g LCD units can hurt companies investing in these facilities.

Have better control over cost, delivery and supply.

The benefits to buyers may include lower export prices.

High component costs, coupled with labor challenges and other factors that lead to pricing pressures, have led many Chinese companies to incorporate upstream and downstream processes in production.

While mainly implemented by large enterprises, vertical integration helps to stabilize the cost and supply of parts, speed up delivery and turnover, and more importantly curb export prices.

For example, the price of LCD TV is expected to decline in the next few years as more companies are investing in high production

A generation display panel in China.

At present, the component is mainly from Taiwan, Korea and Japan, accounting for about 80% of the total cost of the product.

When the display panel supplier raises the offer, Chinese TV makers have no choice but to pay.

However, government subsidies and rebates have encouraged domestic TV makers such as TCL.

Expand to LCD panel production.

Cooperation with Shenzhen Century Technology Investment Co. , Ltd.

TCL set up a joint venture

Shenzhen Huaxing Optoelectronic Technology Co. , Ltd.

Used to make display panels only.

For Building 8.

Huaxing 5g LCD panel facilities in Shenzhen, Guangdong province received 0. 5 billion yuan ($76 million)

Subsidies from the municipal government.

There are now 7 6 to 8.

5g lines in China, 5 of which are locally owned or invested, and 3 are waiting for approval.

There may be 10 high points in this country.

LCD panel facilities by the 2012 s.

When all of this is put into use, the supply may exceed the demand, which may reduce the panel cost, thus reducing the export price of LCD TV.

Absorption of downstream processes can also lead to lower prices.

Dongguan Sobo Electronic Technology Co. , Ltd.

The company used to focus on electronic components of telecom products.

Last year, the company began production of finished products, including dual-workers, power splitter, directional coupler, low-level connectors.

Noise and power amplifier and standing wave alert.

Its customers have been able to save time and money as they no longer need to purchase from different sources.

The disadvantages of integration being able to complete most, if not all, of the manufacturing process do have its disadvantages.

Companies need to spend a lot of money to implement these steps in the following areashouse.

However, the return on investment is not always guaranteed, and it may take several years to achieve it.

In some cases, the return on investment is seen 10 years after spending.

This is one of the reasons why most suppliers who are integrating processes are in the industry where government subsidies or rebates are available.

Beijing Oriental Technology Group Co. , Ltd.

For example, the limited company received a rebate of 1. 6 billion yuan ($242 million)

When it built a 6g LCD panel production line in Hefei, Anhui province.

Overcapacity is another problem because it will push prices to bottom.

This is a boon for buyers, but companies that invest heavily in integrating upstream processes have to wait longer to see positive returns.

Construction boom in 6 to 8.

The 5g facility is an example.

International players are currently actively developing OLED panels.

It is possible to score 8 points at 10: 6.

China\'s 5g production line has been put into operation, and demand in major markets will focus mainly on OLED display screens.

This could lead to a supply glut of 6.

5 to 8g LCD units can hurt companies investing in these facilities.

Custom message