touch screen supply chain

by:LCD Mall

2020-06-28

This white paper provides an overview of the touch screen supply chain.

It describes the key components of the supply chain and the touch screen modules available on the market.

For customers considering touch screen terminal products, it is essential to know the supply chain of capacitive touch screen in detail.

The selected participation model should be

Housing Design capability for module design and supply, value-added services for component suppliers and available options.

The controller IC supplier capacitive touch screen controller is a semiconductor device that detects the position of the finger on the touch screen sensor.

Different suppliers use different silicon structures and sensing methods, which is beyond the scope of this document.

Capacitor controllers can be divided into two categories.

Projection capacitance this method senses the position of the finger on the sensor from the electric field projected by the substrate.

It is usually implemented with one or more patterned ITO layers applied to one or more transparent substrates.

The projection capacitance is very durable because the user touches the top of the glass or plastic substrate and the ITO layer is protected below.

The coordinates are calculated from the measurement signal on the patterned ITO with the determined position.

This makes the projection sensing more accurate and repeatable than other capacitive sensing methods.

For larger screens, more sensing input pins are often required for the projected capacitor controller.

In fact, they are limited to about 10 \"diagonal screens for single-chip solutions.

It is also possible to use multiple controller ICs or unique ITO patterned alternative solutions.

Surface capacitance this method uses a single layer transparent conductor applied to the sensor substrate, usually ITO on glass, film or plastic.

The method is cost-effective and is suitable for mass manufacturing of many famous Technologies.

Since the finger position is determined by four sensors on the corners or edges of the panel, the touch screen can be scaled to 30 or more inches without increasing the number of controller IC pins.

There are also obvious disadvantages, especially for smaller screens.

First, the sensor is realized through ITO on the touch screen substrate.

Although ITO may be protected by a thin hard coating, it is easily scratched by fingers, rings, keys, etc.

In addition, the inherent non-

The linearity of the Surface capacitance sensing field must be corrected by edge mapping, software or hardware methods.

This linear effect becomes more obvious as the screen shrinks.

Other implementation details such as proximity effects and finger shadows must also be addressed.

Flexible printed circuit components (flex)

Used to connect a touch screen sensor to a system controller board.

Flex sometimes installs a touch screen controller as a \"flex module\" supply.

Alternatively, a simple flexible circuit without a controller can be provided to the sensor manufacturer, in which case the controller IC can be built into the customer\'s system controller board.

Sensor suppliers are often referred to as \"glass\" or \"film\" suppliers, members of this supply chain

The housing function of creating a conductive pattern on a transparent substrate material.

The most common conductor is indium-tin oxide (ITO)

Used for its relatively low resistance and high optical clarity.

Other transparent conductors are being used or developed but have not yet become mainstream.

The typical sensor substrate is a derivative of glass, film, or polyester plastic.

Some sensor vendors have additional vertical integration such as touch screen controller ic asic products, controller board electrical engineering, LCD power supply, flexible connector power supply or complete module integration.

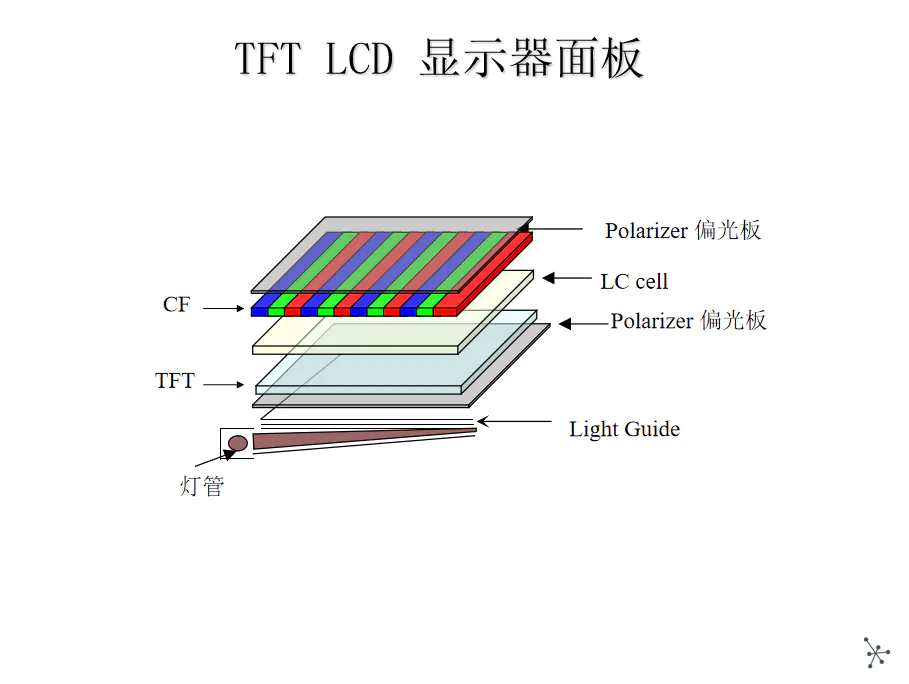

LCD supplier touch screens are often used with video monitors, so it is logical for LCD manufacturers to be critical in the supply chain.

Their core capabilities have included the design of flexible circuits manufactured by deposited patterned ITO and LCD on glass.

So it\'s much easier for them to vertically integrate these key elements of the touchscreen supply chain.

LCD manufacturers choose to simply provide monitors to third parties to integrate into touch screen modules or integrate controllers, sensor glass, or flexible circuits into their assembly process.

Supply chain logistics manufactured by touch screen has several arrangements, depending on the supplier

Customer Sales Engagement, customer preferred business model, and vertical integration for each vendor.

Customers may initially consider buying touch screen controllers, sensors, flex, and LCD directly from each supplier and doing their own design and integration.

While this may bring a cost advantage, it puts all the design, performance and quality issues directly on the customer.

Each touch screen design is unique, so the controller must be configured to work properly with sensor features, LCD noise, and environmental and industrial design factors.

For the first design, this is usually beyond the customer\'s capabilities.

A more commonly used approach is to have customers buy known good \"touch screen modules\" for custom design and testing from one of the supply chain members \".

According to the specific end customer, there are three main varieties of the touch screen module: The Flex module is a combination of the controller IC and the flexible printing circuit.

In order to shorten the design cycle of the touch screen and improve the yield of the touch screen, ITO sensor suppliers mainly purchase Flex modules.

The Flex module consists of a flexible circuit with a touch screen controller IC, which is tested as a known good unit.

Flex modules are usually available to ITO manufacturers or design end customers through Controller IC distribution channels.

For Asian markets, these reps are often \"inventory reps\", a combination of manufacturer reps and value-added supply chain managers.

This product combines the flex module with the ITO sensor.

The use of flex modules improves time-to-market and product reliability while maintaining flexibility in sensor design.

Touch screen modules are usually provided to large OEM or ODM design end customers by suppliers of ITO sensor glass or film.

Some controller IC manufacturers also offer complete touch screen modules to facilitate engineering design, although this product is often limited to large direct customers.

Most big customers have very specific marketing requirements for industrial design and product \"look and feel.

Subsequently, very few companies use off-the-

Shelf touch screen module.

Most are custom designed directly with component suppliers.

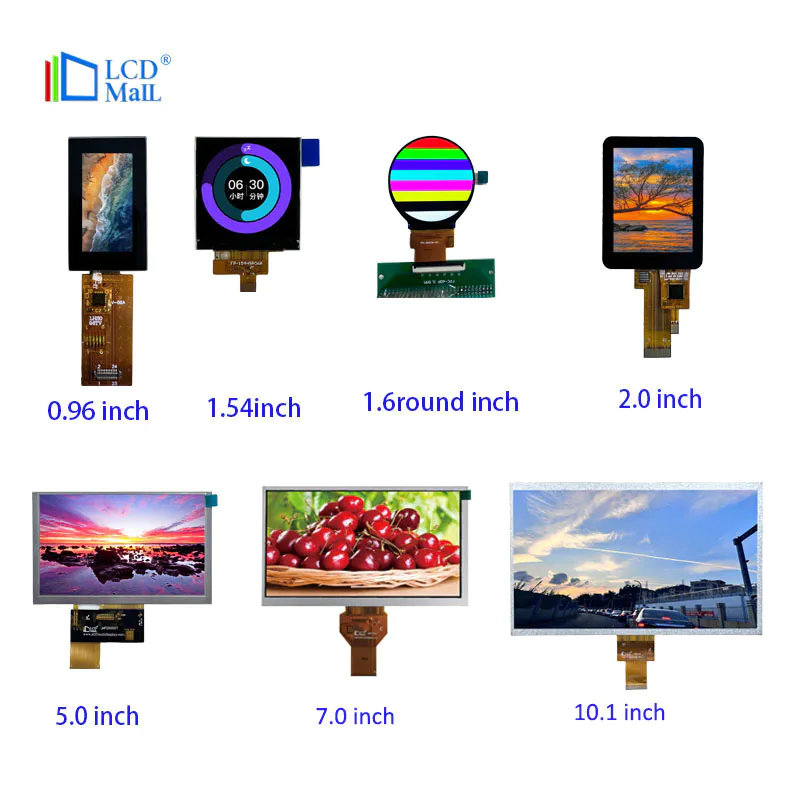

The touch screen LCD display module is the highest level of integration.

It combines the touch screen module with the LCD to create an all-touch sensitive display device.

Design end customers treat this device as a black box, able to display images and send touch coordinates to the main system.

This is highly desirable in terms of manufacturing reliability, as each unit guarantees a known good display and touch interface.

Some LCD manufacturers offer this type of module as a product to the general market.

For large-volume OEM customers, touch sensor manufacturers can also consignment LCD and produce touch screen LCD modules from glass, flexible and controller IC components.

Knowing the details of how touch screens are produced helps you choose the right technology and suppliers for devices that support touch screens.

It describes the key components of the supply chain and the touch screen modules available on the market.

For customers considering touch screen terminal products, it is essential to know the supply chain of capacitive touch screen in detail.

The selected participation model should be

Housing Design capability for module design and supply, value-added services for component suppliers and available options.

The controller IC supplier capacitive touch screen controller is a semiconductor device that detects the position of the finger on the touch screen sensor.

Different suppliers use different silicon structures and sensing methods, which is beyond the scope of this document.

Capacitor controllers can be divided into two categories.

Projection capacitance this method senses the position of the finger on the sensor from the electric field projected by the substrate.

It is usually implemented with one or more patterned ITO layers applied to one or more transparent substrates.

The projection capacitance is very durable because the user touches the top of the glass or plastic substrate and the ITO layer is protected below.

The coordinates are calculated from the measurement signal on the patterned ITO with the determined position.

This makes the projection sensing more accurate and repeatable than other capacitive sensing methods.

For larger screens, more sensing input pins are often required for the projected capacitor controller.

In fact, they are limited to about 10 \"diagonal screens for single-chip solutions.

It is also possible to use multiple controller ICs or unique ITO patterned alternative solutions.

Surface capacitance this method uses a single layer transparent conductor applied to the sensor substrate, usually ITO on glass, film or plastic.

The method is cost-effective and is suitable for mass manufacturing of many famous Technologies.

Since the finger position is determined by four sensors on the corners or edges of the panel, the touch screen can be scaled to 30 or more inches without increasing the number of controller IC pins.

There are also obvious disadvantages, especially for smaller screens.

First, the sensor is realized through ITO on the touch screen substrate.

Although ITO may be protected by a thin hard coating, it is easily scratched by fingers, rings, keys, etc.

In addition, the inherent non-

The linearity of the Surface capacitance sensing field must be corrected by edge mapping, software or hardware methods.

This linear effect becomes more obvious as the screen shrinks.

Other implementation details such as proximity effects and finger shadows must also be addressed.

Flexible printed circuit components (flex)

Used to connect a touch screen sensor to a system controller board.

Flex sometimes installs a touch screen controller as a \"flex module\" supply.

Alternatively, a simple flexible circuit without a controller can be provided to the sensor manufacturer, in which case the controller IC can be built into the customer\'s system controller board.

Sensor suppliers are often referred to as \"glass\" or \"film\" suppliers, members of this supply chain

The housing function of creating a conductive pattern on a transparent substrate material.

The most common conductor is indium-tin oxide (ITO)

Used for its relatively low resistance and high optical clarity.

Other transparent conductors are being used or developed but have not yet become mainstream.

The typical sensor substrate is a derivative of glass, film, or polyester plastic.

Some sensor vendors have additional vertical integration such as touch screen controller ic asic products, controller board electrical engineering, LCD power supply, flexible connector power supply or complete module integration.

LCD supplier touch screens are often used with video monitors, so it is logical for LCD manufacturers to be critical in the supply chain.

Their core capabilities have included the design of flexible circuits manufactured by deposited patterned ITO and LCD on glass.

So it\'s much easier for them to vertically integrate these key elements of the touchscreen supply chain.

LCD manufacturers choose to simply provide monitors to third parties to integrate into touch screen modules or integrate controllers, sensor glass, or flexible circuits into their assembly process.

Supply chain logistics manufactured by touch screen has several arrangements, depending on the supplier

Customer Sales Engagement, customer preferred business model, and vertical integration for each vendor.

Customers may initially consider buying touch screen controllers, sensors, flex, and LCD directly from each supplier and doing their own design and integration.

While this may bring a cost advantage, it puts all the design, performance and quality issues directly on the customer.

Each touch screen design is unique, so the controller must be configured to work properly with sensor features, LCD noise, and environmental and industrial design factors.

For the first design, this is usually beyond the customer\'s capabilities.

A more commonly used approach is to have customers buy known good \"touch screen modules\" for custom design and testing from one of the supply chain members \".

According to the specific end customer, there are three main varieties of the touch screen module: The Flex module is a combination of the controller IC and the flexible printing circuit.

In order to shorten the design cycle of the touch screen and improve the yield of the touch screen, ITO sensor suppliers mainly purchase Flex modules.

The Flex module consists of a flexible circuit with a touch screen controller IC, which is tested as a known good unit.

Flex modules are usually available to ITO manufacturers or design end customers through Controller IC distribution channels.

For Asian markets, these reps are often \"inventory reps\", a combination of manufacturer reps and value-added supply chain managers.

This product combines the flex module with the ITO sensor.

The use of flex modules improves time-to-market and product reliability while maintaining flexibility in sensor design.

Touch screen modules are usually provided to large OEM or ODM design end customers by suppliers of ITO sensor glass or film.

Some controller IC manufacturers also offer complete touch screen modules to facilitate engineering design, although this product is often limited to large direct customers.

Most big customers have very specific marketing requirements for industrial design and product \"look and feel.

Subsequently, very few companies use off-the-

Shelf touch screen module.

Most are custom designed directly with component suppliers.

The touch screen LCD display module is the highest level of integration.

It combines the touch screen module with the LCD to create an all-touch sensitive display device.

Design end customers treat this device as a black box, able to display images and send touch coordinates to the main system.

This is highly desirable in terms of manufacturing reliability, as each unit guarantees a known good display and touch interface.

Some LCD manufacturers offer this type of module as a product to the general market.

For large-volume OEM customers, touch sensor manufacturers can also consignment LCD and produce touch screen LCD modules from glass, flexible and controller IC components.

Knowing the details of how touch screens are produced helps you choose the right technology and suppliers for devices that support touch screens.

Custom message